Electroplated Sn thin films enable low-roughness Nb3Sn superconductor.

Zeming Sun, Ryan D. Porter, Katrina Howard, Thomas Oseroff, and Matthias U. Liepe (CLASSE, Cornell U); Nathan Sitaraman, Michelle Kelly, and Tomas Arias (Department of Physics, Cornell U); Kevin D. Dobson (Institute of Energy Conversion, U Delaware); Xiaoyu Deng (Chemical Engineering, UVA); Aine Connolly and Michael O. Thompson (Materials Science and Engineering, Cornell U)

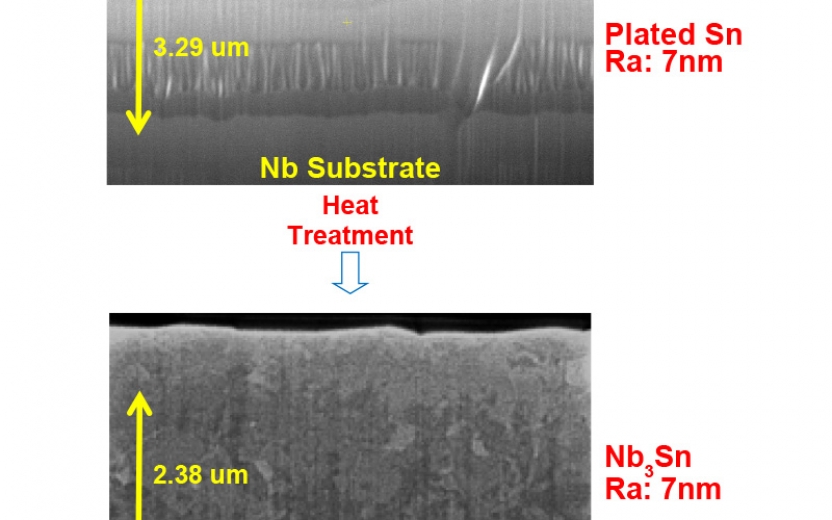

Surface roughness is a critical issue impacting the radio-frequency (RF) performance of superconducting cavities for accelerator applications. In this work, our goal is to reduce the surface roughness of Nb3Sn superconducting films, which are expected to be used in next generation RF cavities. Our strategy is to pre-deposit a uniform Sn film using the low-cost electroplating process and then thermally convert the Sn to Nb3Sn. This electroplated pre-deposition is able to encourage evenly-distributed nucleation events during the heat treatment and thus we achieved an extremely-low-roughness Nb3Sn film with average roughness (Ra) of 7 nm, which is dramatically lower of the state of the art (~300 nm).This electroplating process is now being scaled up to a cavity level. This progress advances the CBB goal of exploration of new promising materials and control of surface conditions in order to achieve high fields and high efficiency for beam acceleration.

Application that could benefit from this advancement include future large scale SRF driven accelerators that need high efficiency in SRF cavity operation (e.g. a future circular collider, FCC); small scale applications of SRF technology in industry, medical application, and for national security, that need robust turn-key SRF operating at ~4K (instead of 2K superfluid helium operation).